Wood Countertop Design Options

Wood Species Options

The lumber used to construct our wood countertops is all premium-grade, FAS boards taken from responsibly managed forests. FSC certified (domestic and exotic species) woods are available upon request. Almost all hardwood species are suitable for wood countertops, so if you have a specific wood in mind, please ask. Samples and samples kits are available. Please contact us for more information. The following are woods we frequently build tops from:

Construction Styles

Find a Style that Fits Your Design Choices

A Wood countertop can be built in many different ways but three distinct construction styles are the most prevalent – flat grain, edge grain, and end grain (butcher block).

Flat Grain Construction

Flat grain wood countertops are made with the face of the wood facing up/down. This is the traditional view of wood that is normally seen in furniture. The Southside Woodshop uses only the highest grade, premium boards for its flat grain tops. Great care is taken to select and assemble lumber that is similar in color and grain. Individual board widths range from 4″ – 10″ and randomly sized boards will be used to make up any given countertop.

A countertop of flat grain construction style comes standard at 1 ½” thick and can be built from 1 1/4″ to 2.5″ thick. Thicknesses beyond 1 ½” are not available in all wood species (for flat grain construction – in edge or end grain construction, we can create countertops that are up to 6” thick!).

Edge Grain Construction

Countertops of an edge grain construction style are made with the edge of the board facing up/down. These long strips offer a grain pattern different than the face, or flat grain, of the board. These strips run the length of the countertop (no joints in the field) unless the overall length is unusually large (>12′). This construction style offers more stability against seasonal wood movement than flat grain construction. Individual board widths range from .75″ – 2″ and randomly sized boards are used to make up any given countertop.

Countertops with an edge grain construction style are available from 1 1/4″ to 6″ in thickness.

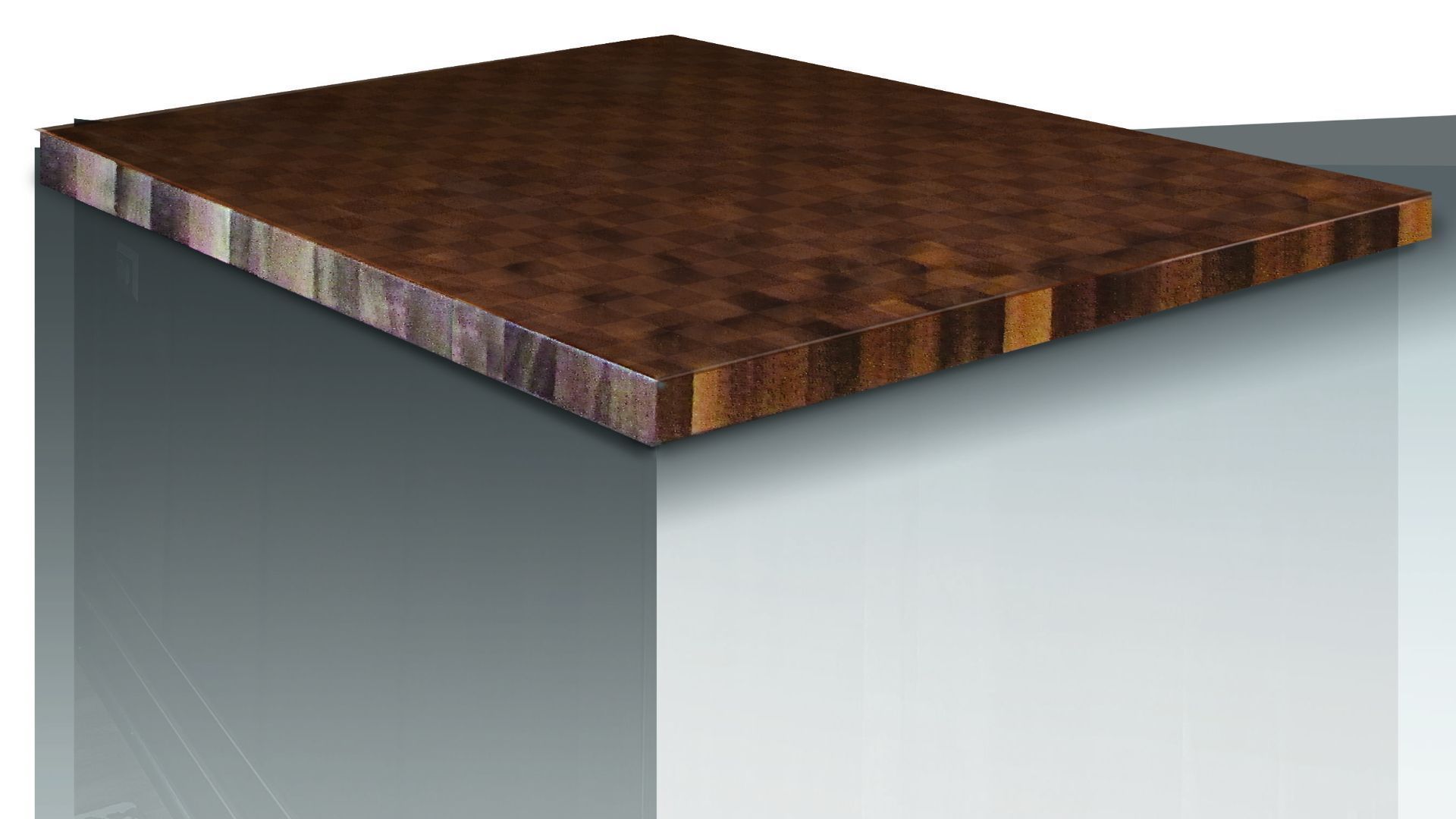

End Grain (Butcher Block) Construction

End grain wood countertops are made with the ends of the board facing up/down. This type of construction is often referred to as “butcher block” construction. Since the end grain is much harder than flat or edge grain, it is the best construction style for those looking to use their countertop as a cutting surface. It will not dull knives as fast as the other surfaces and will not show knife marks as easily as your knives cut with the grain of the wood rather than cutting across it, which causes more wear on the top as well as knives and cutlery.

The individual pieces of a butcher block are typically randomly sized but can be made square to form a checkerboard pattern. Randomly sized blocks are off-set so the individual joints do not line up and unintended patterns aren’t as easy to distinguish. The checkerboard pattern is particularly pleasing when contrasting woods are used.

Tops of an end grain construction style have a minimum thickness of 2.25″ (up to 6″) and are the most expensive form of wood countertop construction.

Special Design Options

Shapes & Sizes

The size and shape of your wood countertop are entirely customizable to suit your design and application. We offer a variety of enhancements, including juice grooves, decorative borders, inlays, integrated knife blocks, waste cut-outs, and drain slots. To streamline installation and protect delicate edges, we precisely craft all necessary cut-outs for sinks and appliances—complete with proper finishing. To ensure accuracy, we require the manufacturer’s templates for any sinks or appliances being installed. For thicker countertops, we also provide additional relief around sink and trash cut-outs to accommodate plumbing fixtures and other hardware.

Our capabilities go beyond these custom additions and we’re always looking for a challenge! If you can imagine it, we can build it.

Finish Options

We have three finish options for our wood countertops and the choice mostly revolves around how you want to use your wood surface:

- Food safe mineral oil – Food safe mineral oil finish is the only real option if you plan on cutting directly on your countertop. This finish is absorbed into the wood and provides limited stain and water protection. It requires a refresher coat of oil to maintain the integrity of the top. Refresher coats will vary by use and location but will typically need to be performed every one to two months. Application is as easy as wipe on, wipe off. We provide your first bottle of food safe mineral oil with your countertop purchase!

- Permanent Finish – Available in dull or satin. This partial-grain fill top coat is recommended on countertops that aren’t going to be used to cut on. It is safe for indirect food contact (kneading dough, etc.), is completely waterproof, and provides excellent protection from stains and household chemicals. This finish is also completely free from formaldehyde and is GREENGUARD interior air quality certified.

- Staining – stock stains and custom staining is available. We can match any stain or color.